Materials

and Process Mechanics Laboratory

University of Toronto

Research Activities

Our research focuses on the mechanics aspects of the performance and processing of materials and manufactured goods. Many of our projects are collaborations with industrial partners, and graduate students lead most of them as part of their M.A.Sc. or Ph.D. research. The publication list below provides a good indication of the nature of our work.

Current and recently completed projects include:

1. Tribology

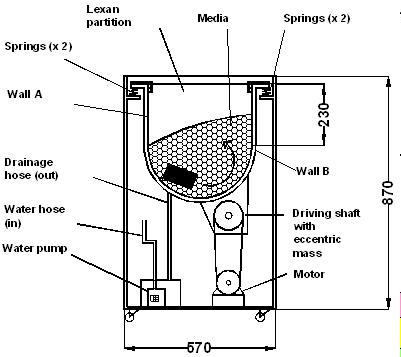

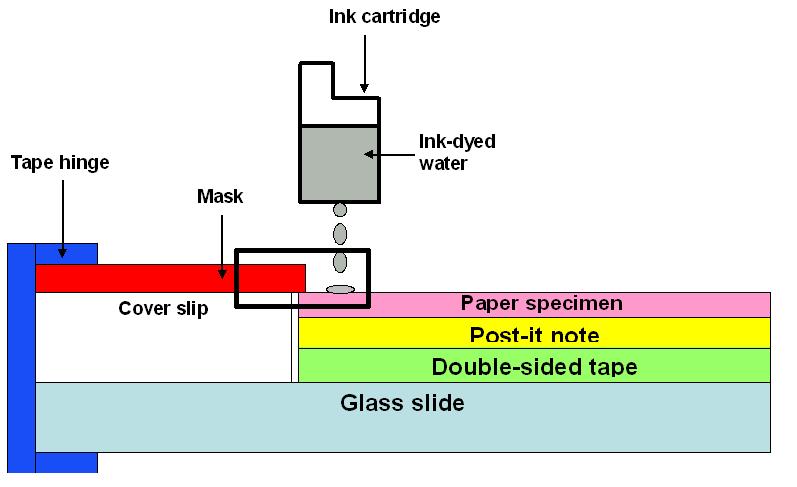

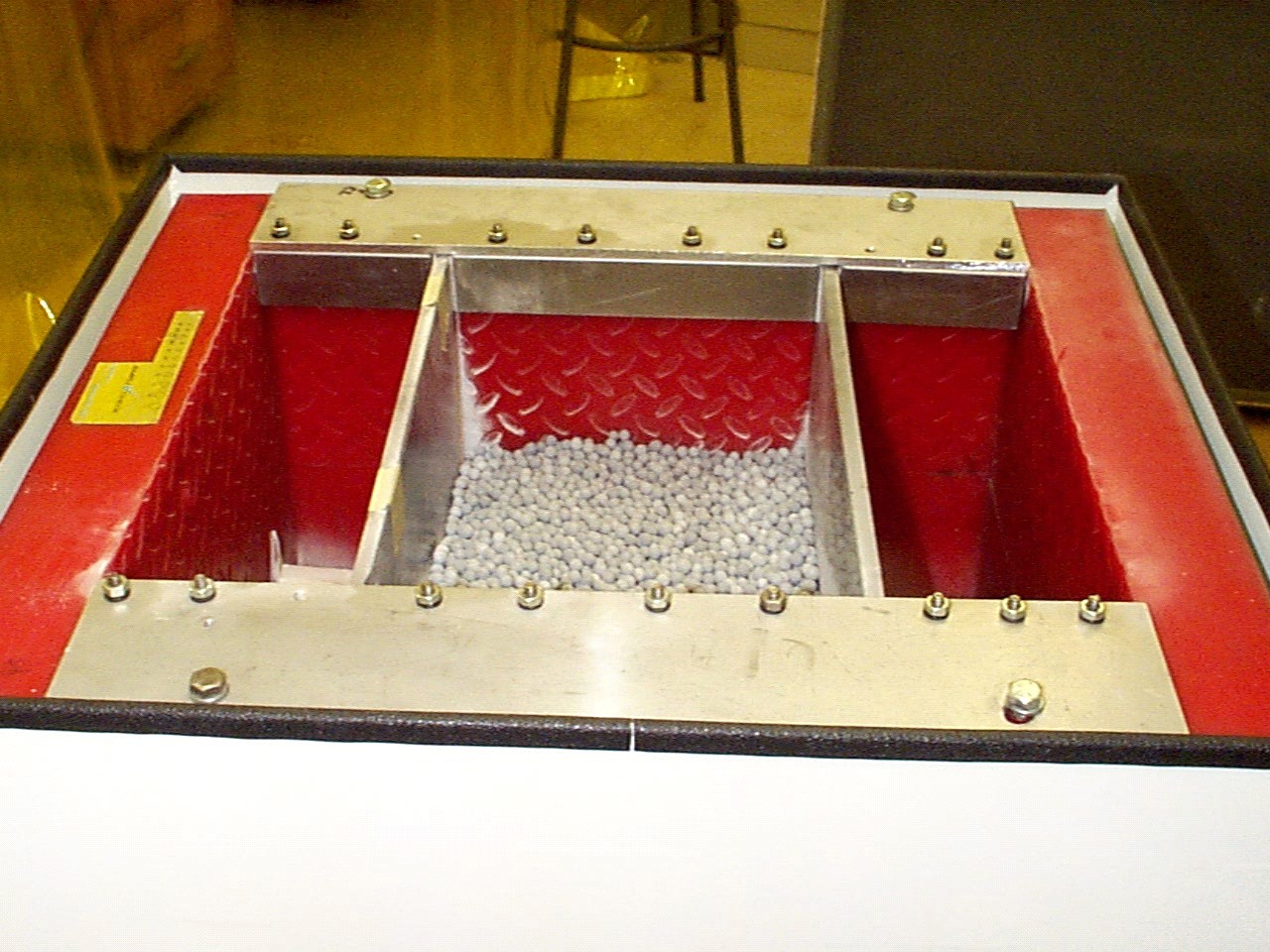

![]() Measuring

the transient contact forces exerted on a part by the abrasive media in

a vibratory

finisher. These data together with measurements of hardness

and

roughness changes as a function of time and finishing conditions are

being used

to understand the mechanics of this widely-used surface finishing

process. Analytical and finite element models are being developed

to

predict the outcome of vibratory finishing as a function of process

parameters. The discrete element method

(DEM) is being used to model the vibrationally fluidized flow of the

media in a

vibratory finisher.

Measuring

the transient contact forces exerted on a part by the abrasive media in

a vibratory

finisher. These data together with measurements of hardness

and

roughness changes as a function of time and finishing conditions are

being used

to understand the mechanics of this widely-used surface finishing

process. Analytical and finite element models are being developed

to

predict the outcome of vibratory finishing as a function of process

parameters. The discrete element method

(DEM) is being used to model the vibrationally fluidized flow of the

media in a

vibratory finisher.

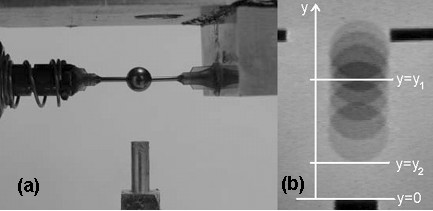

![]() Abrasive jet micro-machining

is being studied

experimentally and analytically in order to develop models to predict

the

eroded surface profile, the rate of material removal, and the roughness

of the

machined surfaces. Channels, holes and

multi-level planar areas are machined in glass, silicon and polymers

with and

without masking. Applications are found

in microfluidics, MEMs and opto-electronic devices.

Abrasive jet micro-machining

is being studied

experimentally and analytically in order to develop models to predict

the

eroded surface profile, the rate of material removal, and the roughness

of the

machined surfaces. Channels, holes and

multi-level planar areas are machined in glass, silicon and polymers

with and

without masking. Applications are found

in microfluidics, MEMs and opto-electronic devices.

![]() Understanding the basic

mechanisms by which high-speed particles remove coatings in the process

of blast

cleaning. This research included the development of models to

predict the

process parameters that most efficiently remove a given coating. Experiments examined particles of glass,

plastic and wheat starch impacting against coatings that are eroded in

one of

three ways: delamination, ploughing erosion, micro-machining erosion.

Understanding the basic

mechanisms by which high-speed particles remove coatings in the process

of blast

cleaning. This research included the development of models to

predict the

process parameters that most efficiently remove a given coating. Experiments examined particles of glass,

plastic and wheat starch impacting against coatings that are eroded in

one of

three ways: delamination, ploughing erosion, micro-machining erosion.

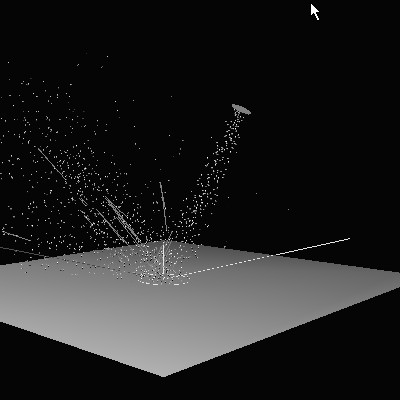

![]() Computer

modeling of the rebound of particle streams from solid surfaces

including collisions with incoming particles. Applications are in

shot

peening, blast cleaning and machining using erosive particle streams.

Computer

modeling of the rebound of particle streams from solid surfaces

including collisions with incoming particles. Applications are in

shot

peening, blast cleaning and machining using erosive particle streams.

2. Microelectronics Packaging

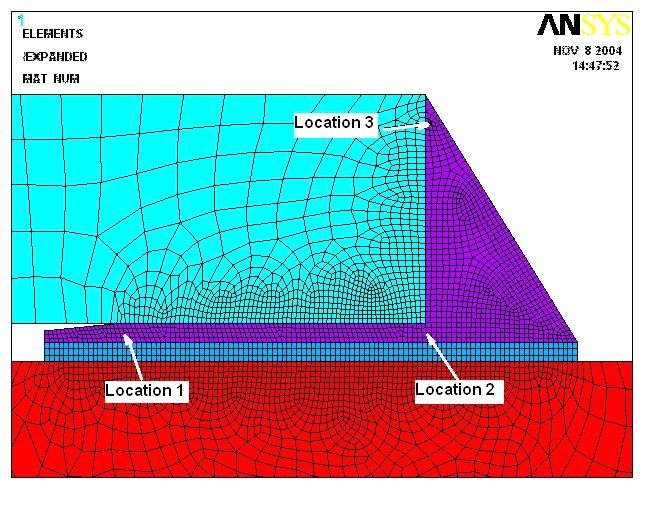

![]() Finite element modelling of

the warpage that can occur in printed circuit boards during

wave soldering.

Finite element modelling of

the warpage that can occur in printed circuit boards during

wave soldering.

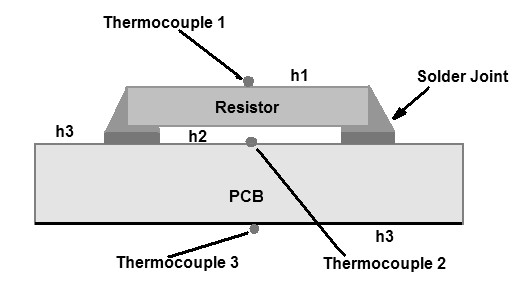

![]() Accelerated thermal

fatigue testing and finite element modeling of solder joint life in

microelectronic components. Our objective is to understand the

role of

test variables such as temperature ramp rate and dwell time so that

manufacturers can reduce product testing times. We are also

obtaining new

data for lead-free solders and assessing the accuracy of thermal

fatigue

models.

Accelerated thermal

fatigue testing and finite element modeling of solder joint life in

microelectronic components. Our objective is to understand the

role of

test variables such as temperature ramp rate and dwell time so that

manufacturers can reduce product testing times. We are also

obtaining new

data for lead-free solders and assessing the accuracy of thermal

fatigue

models.

![]() Distortion in adhesive

connections between optical fibers can cause significant signal

loss.

Our research is determining the causes of such distortion and

developing a

finite element model of the development of distortion during adhesive

curing.

Distortion in adhesive

connections between optical fibers can cause significant signal

loss.

Our research is determining the causes of such distortion and

developing a

finite element model of the development of distortion during adhesive

curing.

![]() Plated-through-vias (PTVs)

provide electrical connections between planes of printed circuit

boards.

Their thermal fatigue performance remains a subject of concern,

particularly

when exposed to the higher manufacturing temperatures associated with

lead-free

solders. Our research is investigating the thermal fatigue of

various

PTVs using air cycling and IST tests (using resistive heating).

Analytical and finite element models are being used to predict the

influence of

material properties and geometric parameters on the thermal fatigue

life.

Plated-through-vias (PTVs)

provide electrical connections between planes of printed circuit

boards.

Their thermal fatigue performance remains a subject of concern,

particularly

when exposed to the higher manufacturing temperatures associated with

lead-free

solders. Our research is investigating the thermal fatigue of

various

PTVs using air cycling and IST tests (using resistive heating).

Analytical and finite element models are being used to predict the

influence of

material properties and geometric parameters on the thermal fatigue

life.

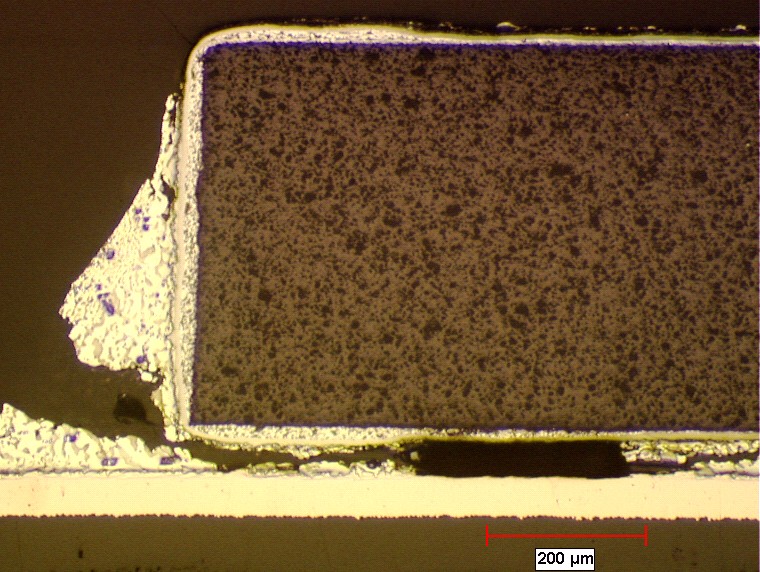

![]() Creep

and thermal fatigue crack initiation

are important causes of solder failure. We are investigating

these phenomena

in tin-lead and lead-free solders as a function of stress state

(tensile,

shear), degree of constraint (plane stress, plane strain), stress level

and

temperature.

Creep

and thermal fatigue crack initiation

are important causes of solder failure. We are investigating

these phenomena

in tin-lead and lead-free solders as a function of stress state

(tensile,

shear), degree of constraint (plane stress, plane strain), stress level

and

temperature.

![]() Experiments and modeling are

being used to

develop methods for predicting the strength of solder joints.

Experiments and modeling are

being used to

develop methods for predicting the strength of solder joints.

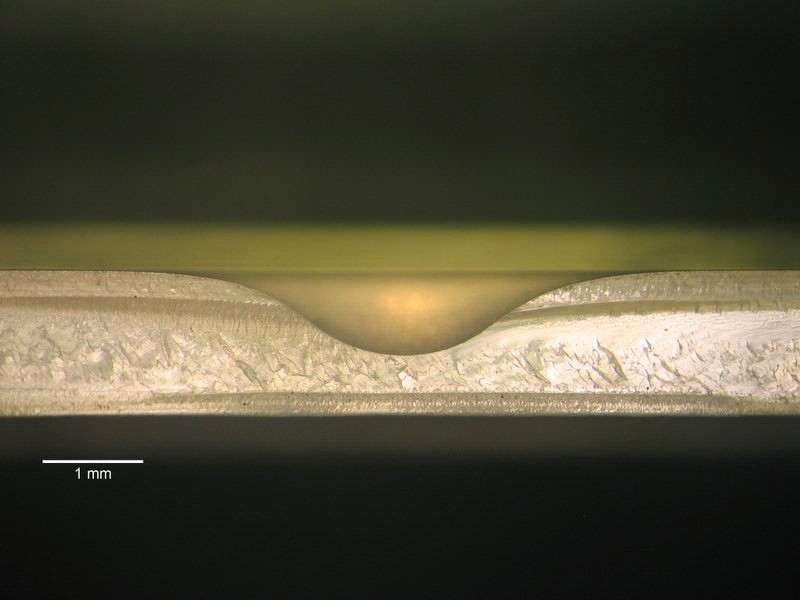

3. Adhesive Bonding

![]() Developing methods for the analysis

and design of structural adhesive joints. Such

methods allow engineers to predict the

fracture strength of adhesive joints under conditions of fatigue,

sustained

loading, and environmental attack. Our research has dealt with

joints in

which adherends remain elastic and those that undergo extensive plastic

deformation, as might be expected in an automobile frame during a

collision. Current research is focusing

on the design of high-strength automotive joints in steel and aluminum

subject

to fatigue and property degradation as a result of water exposure.

Developing methods for the analysis

and design of structural adhesive joints. Such

methods allow engineers to predict the

fracture strength of adhesive joints under conditions of fatigue,

sustained

loading, and environmental attack. Our research has dealt with

joints in

which adherends remain elastic and those that undergo extensive plastic

deformation, as might be expected in an automobile frame during a

collision. Current research is focusing

on the design of high-strength automotive joints in steel and aluminum

subject

to fatigue and property degradation as a result of water exposure.

4. Wood-based Materials

![]() Optical profilometry has been

used to measure small-scale distortion occurring in various papers as

a

result of localized rewetting by an ink-jet printer.

Optical profilometry has been

used to measure small-scale distortion occurring in various papers as

a

result of localized rewetting by an ink-jet printer.

![]() Atomic force microscopy

measure has been used to measure changes in the mechanical

properties of

paper fibers as a function of moisture content.

Atomic force microscopy

measure has been used to measure changes in the mechanical

properties of

paper fibers as a function of moisture content.

![]() We have examined the

technical issues concerning the use of new wood-fibre reinforced

plastics;

e.g. surface pretreatment for painting, the mechanics governing the

performance

of screws, and the effect of different molding conditions.

We have examined the

technical issues concerning the use of new wood-fibre reinforced

plastics;

e.g. surface pretreatment for painting, the mechanics governing the

performance

of screws, and the effect of different molding conditions.

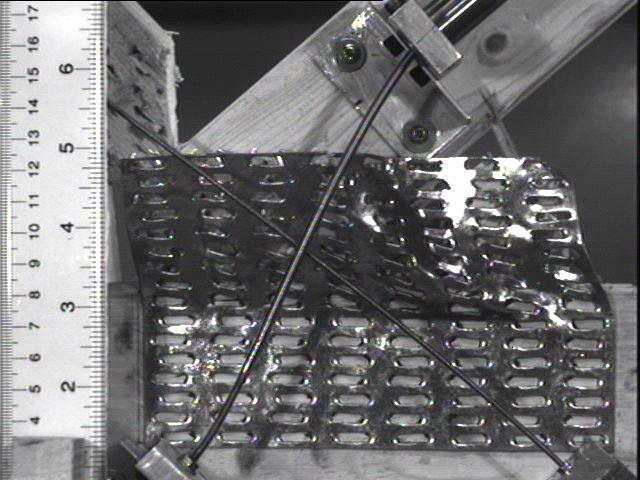

![]() Metal nail plates are used widely to join web and chord

members in

wooden roof and floor trusses. A fundamentally new

approach to the

manufacture of these connections is being evaluated for strength and

stiffness. This information will then be

used to modify existing design methods.

Metal nail plates are used widely to join web and chord

members in

wooden roof and floor trusses. A fundamentally new

approach to the

manufacture of these connections is being evaluated for strength and

stiffness. This information will then be

used to modify existing design methods.

Graduate Students in the Materials and Process Mechanics Lab

Most of the projects in

the Lab

constitute the thesis research of M.A.Sc. and Ph.D. students who are

paid a

Research Assistantship from the project funding. Post-doctoral

fellows

and visiting professors have also made many important contributions to

our

work. The following link provides a list of the past and present

(indicated by *) graduate students who have worked in the Materials and

Process

Mechanics Laboratory. Projects related

to abrasive jet micro-machining also involve the affiliated laboratory

of Prof.

M. Papini (

Journal

and Book Publications

Journal

Papers

Journal

Papers Spelt.pdf

Books

and Book Chapters

Books and Book Chapters Spelt.pdf

Research Facilities

![]() a wide variety of load frames and accessories for mechanical

testing

a wide variety of load frames and accessories for mechanical

testing

![]() finite element modeling

finite element modeling

![]() microhardness tester

microhardness tester

![]() surface roughness and microtopography measurement

surface roughness and microtopography measurement

![]() instrumented vibratory finishers

instrumented vibratory finishers

![]() thermal shock chamber

thermal shock chamber

![]() adhesive bonding facilities

adhesive bonding facilities

![]() gas gun and high-speed photographic facility for blast cleaning

research

gas gun and high-speed photographic facility for blast cleaning

research

![]() computer-controlled abrasive jet micro-machining

computer-controlled abrasive jet micro-machining

![]() image analysis

image analysis

Contact: Professor

J.

K. Spelt

spelt@mie.utoronto.ca